Retailers and wholesalers responding in a time of need |

| By Kristin Ely |

|

|

Beach, coastal and nautical companies have shifted gears to help out during the COVID-19 crisis. Almost as quickly as the coronavirus disrupted business for retailers and wholesalers, many stepped up to the plate to help their neighbors in great need of personal protective equipment (PPE). When the state of Ohio shut down all but essential businesses to curb the virus from spreading, Dalton, Ohio-based Coastal home decor manufacturer P. Graham Dunn had to bring its assembly line to a halt.  P. Graham Dunn has converted its assembly lines from home decor to face shields for healthcare workers, allowing one third of its employees to come back to work.

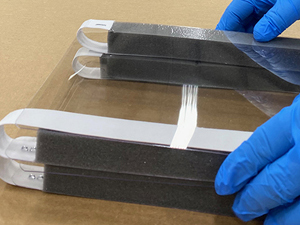

Some of the company’s 300 workers were furloughed as a result. But then an opportunity came along from Laird Plastics, a local plastics manufacturer. The company was looking for “anyone and everyone” who could assist with making protective plastic face shields for health care workers, according to Anthony Burdette, P. Graham Dunn vice president of marketing and product development. “It was a natural fit for us because we’ve got a workforce here that unfortunately does not have work at the time because orders are being delayed and manufacturing home decor is not something we can really do right now. All of our orders have been put on hold for the most part,” he says. Laird Plastics delivers the plastic and elastic to P. Graham Dunn, and the staples used to attach the elastic to the plastic face shields come from community donations. P. Graham Dunn has been able to put a third of its workforce, or about 75 employees, back to work making the face shields. The transition from making home decor to assembling PPE has been relatively easy for the employees and the equipment, according to Burdette. He explains that unlike a company like Pepsi, which has a highly automated process, P. Graham Dunn’s assembly of products is more fluid. One day workers might be making a standardized plaque and the next day they might be assembling a pallet sign. “We have a very flexible assembly line, and we’ve been able to convert those lines into lines that are now producing the PPE,” says Burdette. And they’ve been doing a bang-up job. In just two weeks, employees have assembled more than 300,000 units, and there are no plans to stop anytime soon. “Until there is no more demand we are going to keep producing,” Burdette says. The shields are bagged and delivered by truck to medical facilities as far away as Connecticut and Maryland. Employees have been very receptive to their new assignment. “The response has been positive. It’s been a fantastic way that we as a company can still keep our employees engaged with our business and continue to provide them with a paycheck,” says Burdett. “From a worldwide or nationwide standpoint, it’s just been an opportunity that we can help fight the coronavirus and work together and be part of the bigger picture, which is something very unique.”  Salt N Rays has donated fabric normally used for its towels to people sewing masks that will be used for donations to people in need. P. Graham Dunn is far from alone when it comes to the industry wanting to contribute. Christy LaSalle, owner of Salt N Rays, wasted no time donating a surplus of the brand’s UPF 50 buffs to a Bridgeport, Connecticut, hospital. The buffs, which come in bright, beachy patterns, can be worn in a variety of ways, like around the neck or as a headcover. LaSalle had about 100 buffs in stock and decided to offer them to a local hospital. At first the hospital turned her down, but about 48 hours later, a staff member called her back and said, “We’ll take everything you have.” La Salle notes, “They aren’t really made to protect your breathing. Most of the nurses are wearing them in their hair.” She also donated fabric that would normally go into creating towels to people who are sewing surgical masks for people at risk. “I had all this fabric to make towels, so I thought it might as well be put to good use,” she says. She never thought the buffs and fabric would end up one day helping protect people from something more severe than the sun, but they’ve proven to be a lifesaver, literally. Prior to the pandemic, LaSalle had never sold a single item on Amazon. Once the media started promoting using bandanas and scarves as a way to cover the nose and mouth, that all changed. “I had never sold a single buff on Amazon and now they are gone,” she says. She adds she is glad they are being put to good use. Clothing company Lilly Pulitzer also took notice of the growth in popularity of cloth masks.The company’s team of factories and employees quickly sprung into action and volunteered their time to create 27,500 mask covers, which have been all donated to health care workers and first responders at over 60 organizations. And it hasn’t stopped there. Several companies have begun making fabric masks for any person who wants them, not just health care workers. Demand for masks soared when the CDC recommended everyone wear them when outside the home. Cherapy, which normally makes therapeutic heat pillows using cherry pits, is now making masks with its fun tropical fabrics. The company has sold out of many of the patterns already. Beachables, in Charleston, South Carolina, is another wholesaler that has turned its attention from its beach towel tote bags to selling masks. The company has also volunteered its time repairing masks for a local hospital.

Just Picked Gifts has partnered with a local sewing company to make and sell masks at its Yarmouth, Massachusetts store. The response has been overwhelming. Joining the throngs of ever-important mask-makers is Just Picked Gifts, which operates three stores in one location in Yarmouthport, Massachusetts. The company, which sells a variety of gifts and apparel, partnered with a local sewing company that normally makes pillows, tea towels and pet bandanas after seeing their popularity explode on social media. “We were talking to the owner and she is a bit shut down right now, so this gave her an opportunity to work,” says Lisa Medland, a manager at Just Picked Gifts. Folks could order them online or through Instagram. The masks are shipped or picked up curbside at the store. Just Picked Gifts donates 10% of the proceeds from the sale of the masks to a local hospital. Once they started making and selling the masks, Just Picked Gifts and the sewing company were quickly flooded with orders. “We had seamstresses sewing night and day just to try to keep up with the orders,” Medland says. The store is not accepting any more orders until the existing orders are fulfilled. ■ If you are a beach, coastal or nautical retailer or wholesaler who is contributing in a positive way to the pandemic, we’d like to hear from you. Email Executive Editor Kristin Ely at kristin@seasideretailer.com. And if you know of a retailer worthy of recognition, you can nominate them for a Starfish Award at www.seasideretailer.com/starfish-award. |